Membership

Help

Jinan Acme CNC Equipment Co., Ltd.

Jinan Acme CNC Equipment Co., Ltd.

3000w Tube laser cutting machine advantage

New generation upgraded professional metal tube and pipe fiber laser cutting machine some details are optimized. More stable,more efficient, accurate and intelligent.

Exclusive patented new design,more intelligent, stable and faster,many different types of tubes and pipes are available.

Patented Fast large diameters double pneumatic auto-centering chuck, more stable clamping, more convenient operation, more accurate cutting.

The failure rate is low. With mature patent technology and 15 years of experience,we make the machine operation more stable and smoother.

Thickened machine bed , no deformation for 30 years, greatly extending the service life of the machine.

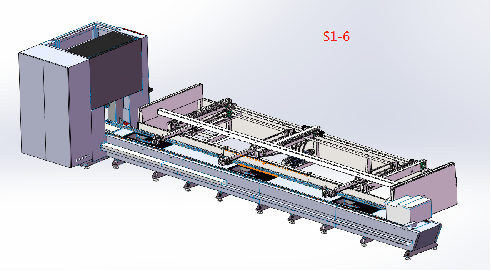

3000w Tube laser cutting machine configuration

Mode | LT-6012DB |

Control System | Fscut 3000S China (the fifth generation advanced motion control ) |

Cutting Software | Fscut TubePro 3D Cutting China(Advanced Professional Version-More powerful function, more convenient operation) |

Nesting Software | TubesT China (Professional high-end version-Faster ,smarter,easier to operate and more functions. more optimized solution helps you save materials |

Laser Source | MAX China(China Top Brand for its stable excellent performance) |

Laser Head | Raytools Autofocus Laser Head BM110 Switzerland |

Water Chiller | Hanli china |

Servo Motor | YASKAWA x5 Japan |

Chuck | Both Automatic Pneumatic Chuck |

Reducer | Shimpo Reducer Japan |

Guide Rail | T-WIN Taiwan(Real taiwan original) |

Rack and Gear | T-WIN Taiwan (Real taiwan original) |

3000w Tube laser cutting machine cutting range

Semi-loading system for 3000w tube laser cutting machine

| Feeding pipe length | L≤6200mm |

| Tube Type | 1. Closed pipes, square pipes, round pipes, rectangular pipes and other pipes that are convenient for clamping 2. Non-closed pipes, channel steel, angle steel, H-shaped steel and other convenient clamping pipes |

| Pipe section size | ≤100x100(Square Section) |

| Bearing Weight | ≤650kg |

| Tubes Quantity(eg. square tube 50x50mm) | 11pcs |

| Maximum drag speed of feeder | ≤16m/min |

| Maximum feeding speed of feeder | ≤28m/min |

| Feeding Time | 15S |

| Loading system total Size | 6410mmX1650mmX830mm |

| Loading system total Weigtht | 0.8T |

| Power | 2KW |

| Matched machine | 6m D model tube laser cutting machine |

| Curvature of loading material | The curvature of the profile shall not be greater than 2mm per meter, and the total curvature shall not be greater than 0.15% of the total length (refer to national standards) |