Membership

Help

Jinan Acme CNC Equipment Co., Ltd.

Jinan Acme CNC Equipment Co., Ltd.

ACME Entry Level Metal Tube Fiber Laser Cutting Machine

LT-6017D is designed as professional metal tube fiber laser cutting machine

Cutting metal pipe tubes length 6000mm,

Output/receiving platform length 3000mm

Tube diameter 10-165mm

Tube shape:Round, Square, Rectangle, Oval,Angle steel, Channel steel and so on.

Technical Parameters

1 | CONTROL SYSTEM | FSCUT3000S Tube Cutting Control System | ||

2 | SOFTWARE | TubePro Tube cutting software | ||

3 | LASER SOURCE | MAXPHOTONICS 2000W | ||

4 | LASER HEAD | Raytools Swiss Auto-focusing | ||

5 | WATER CHILLER | HANLI China | ||

6 | SERVO MOTOR | Yaskawa Servo Motor, Japan 2000W*1 set (Y) 1500W*1 set (Back Chuck) 3000W*1set (Front Chuck) 750W*1 set(X) 400W*1 set(Z) | ||

7 | REDUCER | SHIMPO Japan/MOTOREDUCER France | ||

8 | GUIDE RAIL | HIWIN TAIWAN | ||

9 | GEAR AND RACK | YYC | ||

10 | TRANSMISSION | HELICAL RACK | ||

11 | ELECTRICAL PARTS | SCHNEIDER France | ||

12 | OIL LUBRICATION SYSTEM | Automatic oil self-lubrication system | ||

13 | DUST EXTRACTION SYSTEM | Exhaust Air Fan | ||

14 | PIPE | CUTTING LENGTH(mm) | 6000 | |

CUTTING DIAMETER(mm) | 10-165mm | |||

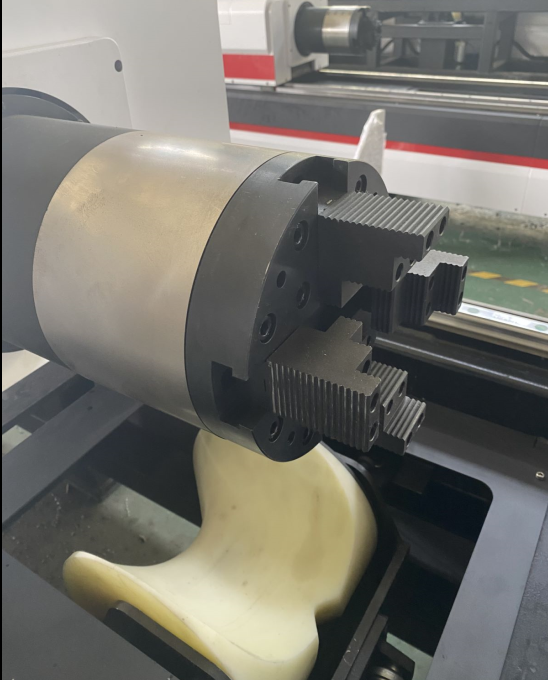

15 | CHUCK | Type | 8 Cylindes Pneumatic chuck* 2pcs, Auto-Centering | |

MIN. Tail Length(mm) | 65mm | |||

Rated Rotation Speed(r/min) | 80 | |||

MAX. Rotation Speed(r/min) | 100 | |||

Bearing Capacity(Both) | 300kg | |||

16 | X-axis | Travel(mm) | 380 | |

No-Load MAX. Speed (m/min) | 90 | |||

17 | Y-axis | Travel(mm) | 6700 | |

No-Load MAX. Speed (m/min) | 90 | |||

18 | Z-axis | Travel(mm) | 250 | |

No-Load MAX. Speed (m/min) | 60 | |||

19 | POSITIONING ACCURACY | ±0.03/1000mm | ||

20 | REPEAT POSITIONING ACCURACY | ±0.02mm | ||

21 | POWER SUPPLY | 380V, 50/60HZ (can be customized voltage) | ||

22 | AUXILIARY CUTTING GAS | Oxygen / Nitrogen / Compressed Air | ||

23 | SUPPORTED FILE FORMAT | .IGS | ||

24 | DIMENSION | Tube cutter: 9965x1450x1720mm Tube cutter with loading system:10868x3275x2133mm | ||

25 | G.W. | 2750KG | ||

Warranty and Installation

Warranty | 24 months for the whole machine (except consumable wearing parts) |

Machine Installation & Training | Method 1: On-line guidance We have professional English speaking engineer team to provide One To One Online Guidance Service for the machine installation, commissioning and operation training. Method 2: Door-door service Our agent can provide the on-door service with the extra charge according to different machine, places and agent standard charges.Normally 7 days can finish. |

After-sale service | Machine installation and Training operators English Speaking Engineers available for oversea services. Consumable parts supply. Life-long free technical support. |

Shipping | 1x40’HQ container |

HS Code | .90 |

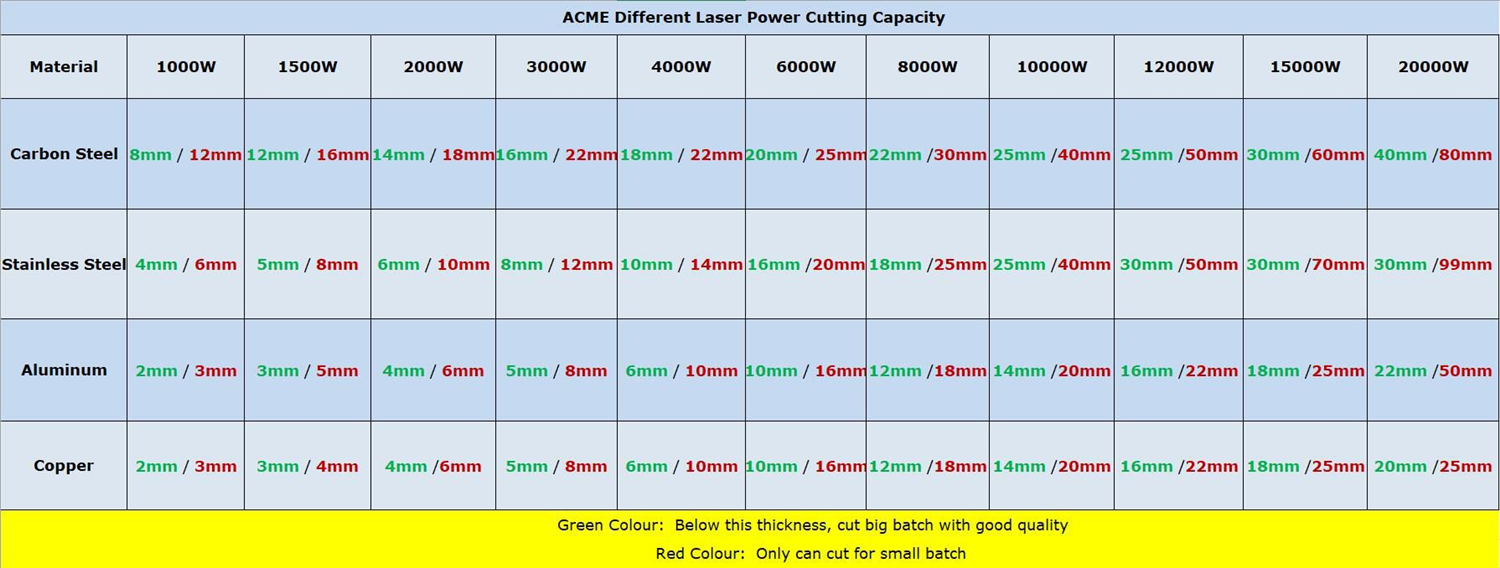

Different Laser Power Cutting Capacity Table

Machine Running Cost

2000W Metal Tube Fiber laser Cutting Machine using cost | ||||

Assisted Gas

Consumption | Option 1: Use compressed clean air cutting | Option 2: Using O2 cutting | Option 3: Using N2 cutting | |

Power Consumption | Laser Module | 6kw | 6kw | 6kw |

Water Chiller Group | 3.3kw | 3.3kw | 3.3kw | |

Host Machine | 8kw | 8kw | 8kw | |

Dust Exhausting Equipment | 3kw | 3kw | 3kw | |

Consumable Part | 2.5RMB/h | 2.5RMB/h | 2.5RMB/h | |

Gas Consumption | 5.5kw | About 6.7RMB/h | About 64RMB/h | |

Total Power | 25.8kw | 20.3kw | 20.3kw | |

AveragePower Consumption (Take 60% ) | 25.8*60%=15.48kw | 20.3*60%=12.18kw | 20.3*60%=12.18kw | |

All Running Cost (Use 1RMB/h) | 15.48+2.5=17.98RMB/h | 12.18+2.5+6.7=21.38RMB/h | 12.18+2.5+64=78.68RMB/h | |

Machine Cutting Sample

Machine Video