Membership

Help

CKD LASER CO., LTD

CKD LASER CO., LTD

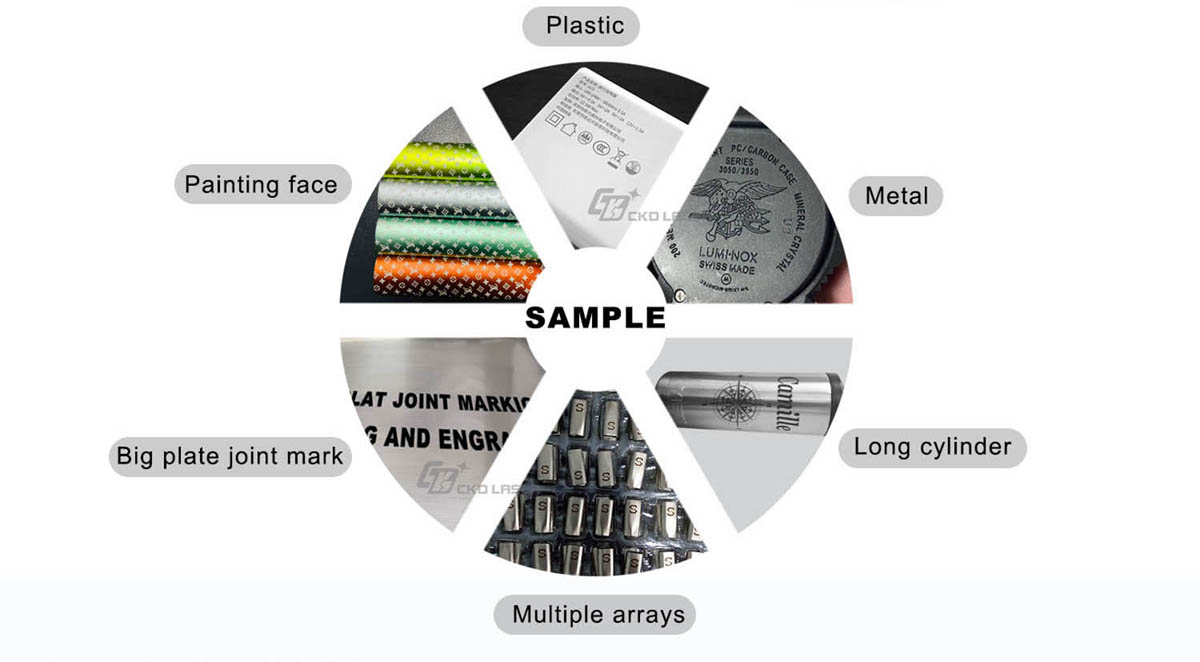

CKD-TLMC V21.11 coordinates 4 axes working together. Usually for high precision terms, this laser machine marks logo on or cut material of metal, plastic, ceramic, wood,glass, painting face, leather and so on. It perfectly solves distortion causedby laser divergence angle, successfully realizes large-scale joint marking, and firstly achieves easy operation for multi-purpose, which it can surface mark, deeplyengrave, cut and weld in the same machine.

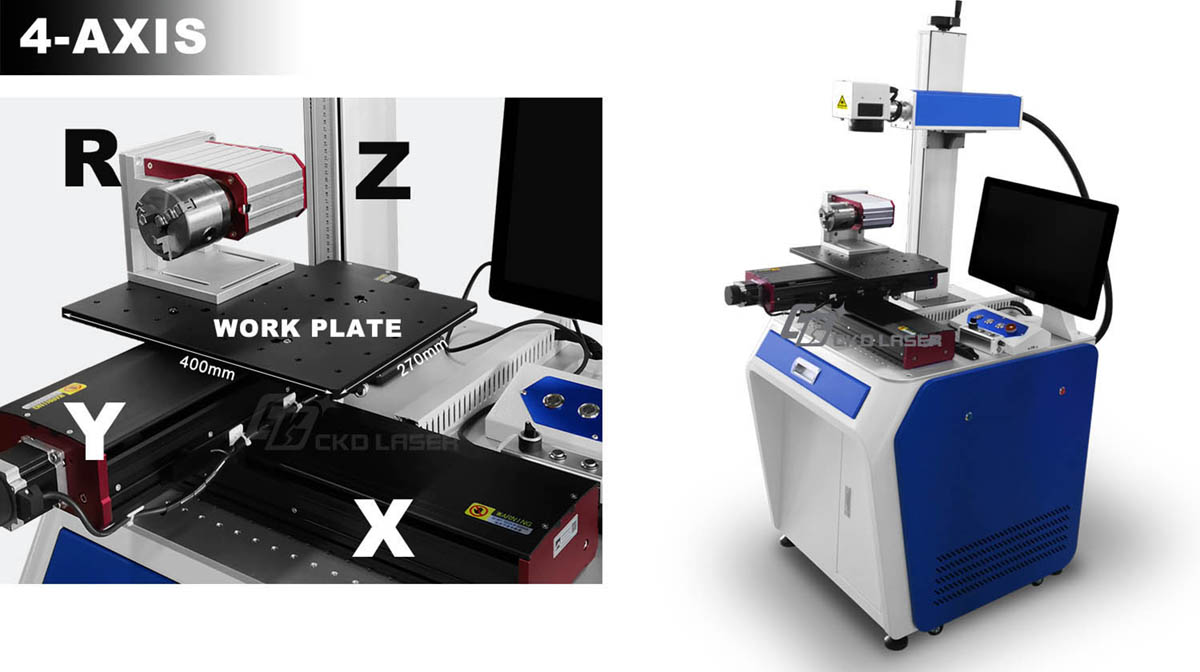

X-axis:delivery material right-left direction

Y-axis:delivery material front-back direction

Z-axis:delivery material up-down direction, focusing

R-axis:360°rotarymarking, with reduction gears, high precision

Marking function: vector, bit map / photo, QR, bar code, series number, annulus,color… supports kinds of automatic generation.

Engraving function: big power for deeply engrave on metal,glass or wood. (You need to choose right configuration after let us knowingyour mainly application, attached the configuration table the end.)

Cutting function: cut metal or no-metal, often for jewelry, electron component, decorations, gifts or crafts.

Welding function: spot weld metal, such as battery, circuit board componentand so on.

Peeling function: remove the painting face on metal, plastic, mirror orglass. For examples, bottle of lip glaze or makeup, conductive component and soon.

Auxiliary function: phone case or pad case separating, laser cleaning, laser film painting and so on.

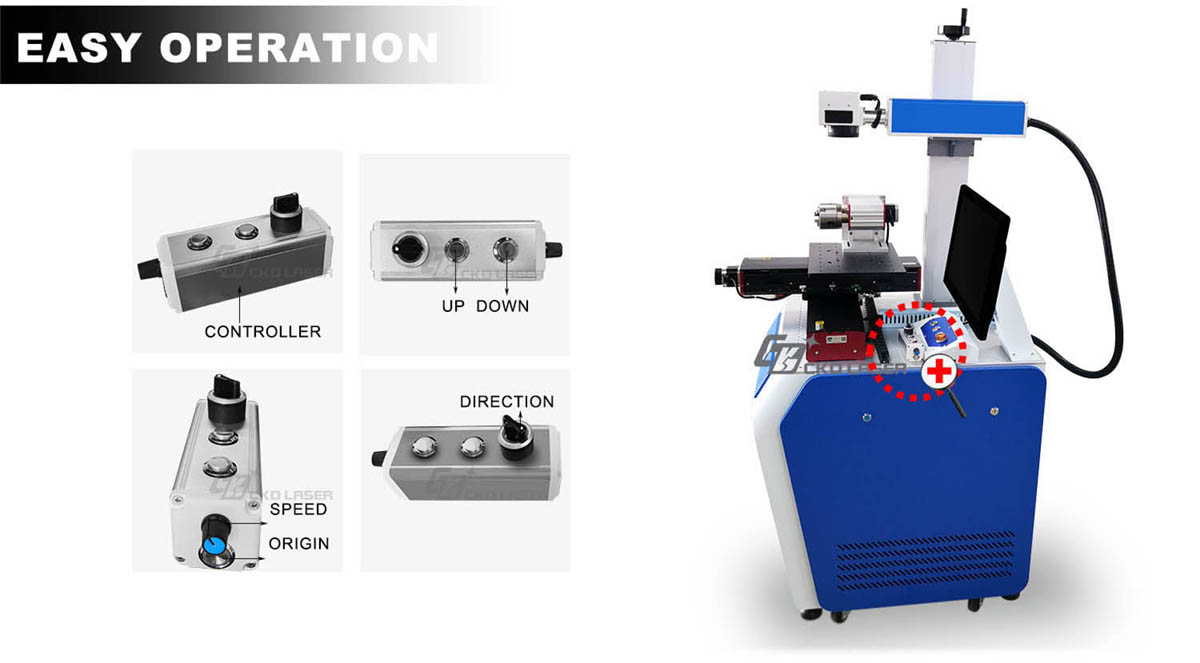

Evenit has 4-axis, one small box can help you to operate easily, the basic data of marking software has been set well in advance according your application. (You should tell us your application accurately and with full details to help yourself.)

Incomparable both inside the outside manufacture, use top quality of all components andparts.

All accessories are chosen after various evaluations and tests according to kindsof application, in order to get the most suitable ones for the whole system, therefore, we do not accept specified parts or accessories, avoid to break coordination orharm the performance.

Configuration of CKD-TLMC series, V21.11 version:

Type | Laser (Optional) | Moving System | Marking System | Control System | Marking Speed (Optional) |

CKD-TLMC-5 | 5W, UV laser | X-Axis | EzCad2 | Computer | 1-2000mm/s |

CKD-TLMC-10 | 10W, UV laser | ||||

CKD-TLMC-30 | 30W, fiber, Q-switched | 1-2000mm/s | |||

30W, fiber, MOPA | |||||

30W, CO2 | 1-2000mm/s | ||||

CKD-TLMC-50 | 50W, fiber, Q-switched | 1-2000mm/s | |||

CKD-TLMC-60 | 60W, fiber, MOPA | ||||

60W, CO2 | 1-2000mm/s | ||||

CKD-TLMC-100 | 100W, fiber, MOPA | 1-2000mm/s | |||

CKD-TLMC-120 | 120W, fiber, MOPA |

Length | Travel Distance | Chuck | Work Plate | |

X-Axis | 500mm | 1-300mm | -- | 270*400mm |

Y-Axis | 500mm | 1-300mm | ||

Z-Axis | 800mm | 1-390mm | -- | |

R-Axis | -- | -- | 80mm |

Packing Size | 85*83*195cm |

Gross Weight | 180Kg |

Electricity | 110V, 60Hz or 220V, 50Hz (Only can choose one) |

Notice: Please tellus your electricity voltagewith inquiry.

There are some related types for different application, if you want simple or higher functionsbased on CKD-TLMC V21.11, please refer following table or send your details demandto us for consulting.

Focus | Speed | Axis | Identification system | Marking system | Optical system | |

TLMC, V18.03 | Manual | 1-2000 mm/s | R-axis or none | None | EzCad2 | Normal |

TLMC, V20.04 | Motorized | 1-4000 mm/s | R-axis | None | EzCad2 / EzCad3 | Digital, self-repairing |

TLMC, V20.08 | Manual / Motorized | R-axis | Vision location | EzCad2 | Normal or Digital | |

TLMC, V21.06 | R-axis | Vision location | ||||

TLMC, V21.10 | None | |||||

TLMC, V21.11 | Manual & motorized | 1-2000 mm/s | X-Axis | None | EzCad2 / EzCad3 |

In order to choose right configuration, please tell us your application before price inquiry, such as:

Material (point out which is mainly), work load per day, process content, precision demand, and other specific demand.